Project Description

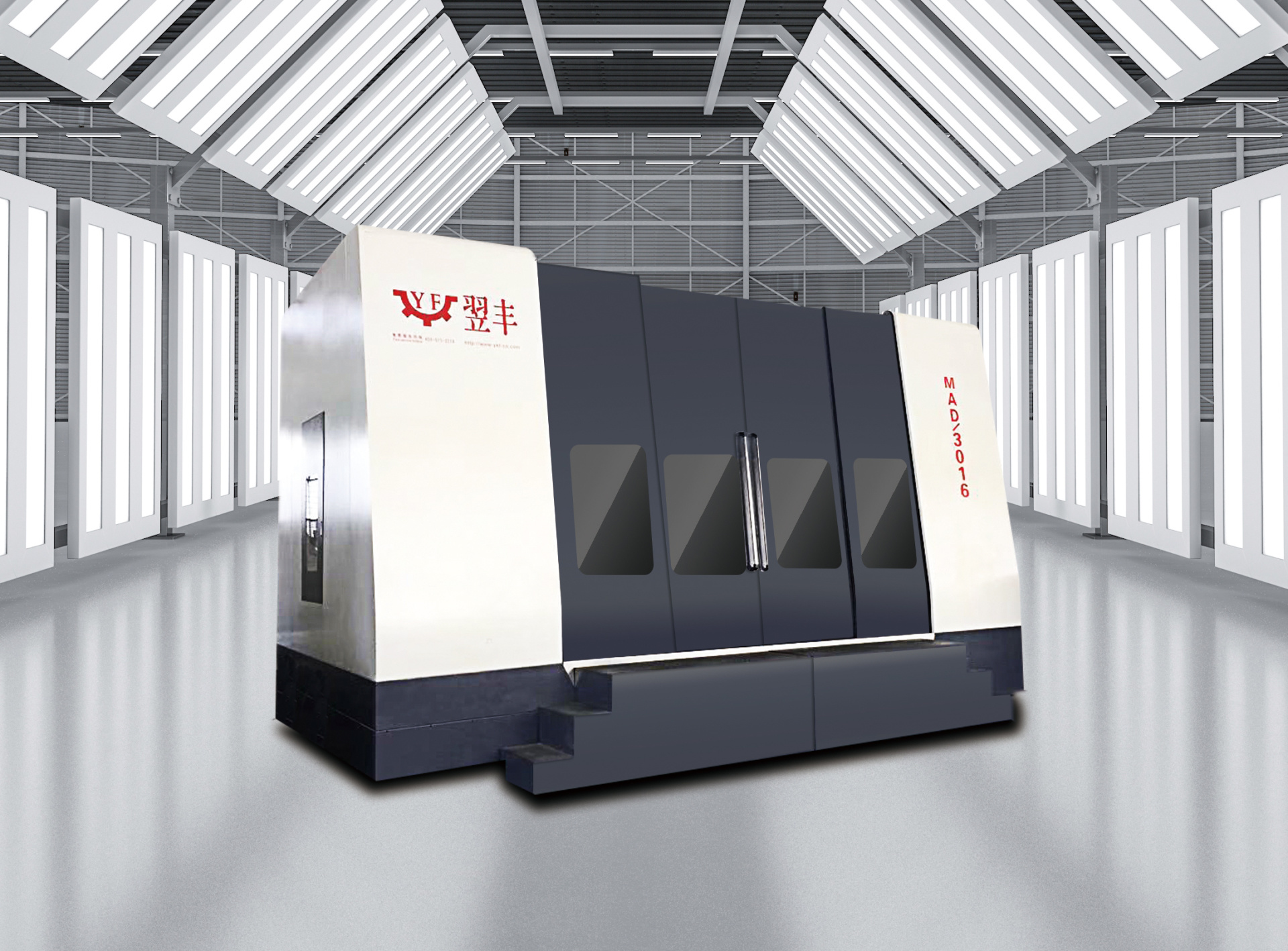

Model purchased: MAD-3016

Company Profile: Zhejiang Taoshi Mold Group (formerly Zhejiang Huangyan Mold No. 2 Factory) is located in Huangyan, known as the "Hometown of Molds in China." It is one of the largest plastic mold design and manufacturing enterprises in China, with a superior geographical location and convenient transportation. Taoshi Group is a comprehensive private joint-stock enterprise integrating science, industry, and trade. It has more than 500 employees, including over 120 engineering and technical personnel and more than 50 senior management and professional technical personnel. The group has three divisions (Home Appliance Mold Division, Automotive Mold Division, and Daily Necessities Mold Division) and five subsidiaries. It has a registered capital of 100 million RMB, an annual output value of 200 million RMB, and has passed ISO9001 quality management system certification. The company possesses internationally advanced CAD/CAM/CAE systems, including more than 20 sets of SUN workstations from the United States, and specialized design software such as PRO/E, UG, CIMATRON, and FFCAM. A powerful group of CNC machining and high-speed machining equipment has been established, which can increase production efficiency by 40%. The company also owns dozens of CNC machining equipment, CNC electro-machining equipment, and general-purpose processing equipment, such as high-speed vertical machining centers from Japan, fully CNC spark machines from Switzerland, integrated mold processing centers, deep-hole drilling machines, and three-coordinate measuring instruments. The company attaches great importance to independent intellectual property rights. A large and efficient design and development center (with more than 40 senior professional design talents and specialized design and manufacturing software such as Pro/E, UG, CIMATRON, and Crmould) can perform three-dimensional part-based parallel design of molds. Based on the three-dimensional and part-based design of molds, we utilize network technology to develop software service function modules. Using graphite machining machines, we can achieve fully enclosed high-speed and high-precision electrode machining, resulting in electrodes with good surface smoothness, thereby improving product accuracy and quality. We have also introduced laser detection and scanning systems to improve mold detection methods and ensure product accuracy and precision. Taoshi has always been committed to creating value for customers with advanced technology and exquisite products, providing system solutions in the research, development, design, and manufacturing of molds and plastic parts. Products cover multiple industries, including automobiles, home appliances (TVs, air conditioners, washing machines, refrigerators, vacuum cleaners), electronic communications, motorcycles, daily necessities, and boxes and pipes. More than 20 products have been awarded intellectual property patents, with an average of six new product series developed annually. Sales of TV set shells account for about 1/10 of the national total. Home appliance and automotive plastic parts have been exported to countries and regions such as Japan, the United States, France, Canada, Italy, Singapore, Egypt, and India. The company has become a supplier to many well-known domestic and foreign companies, including VALEO, TOYOTA, HONDA, BENZ, RENAULT, RESTEL, VIDEOCON, Hisense, Xiaohua Electronics, Shanghai Radio and Television, and Panda. The company has been listed as a backbone enterprise of the national plastic mold characteristic base, a national torch plan project unit, a Zhejiang Provincial High-tech Enterprise, an advanced enterprise in Zhejiang Provincial quality management, a "128" project in Taizhou City, and a "Top Ten" enterprise in Huangyan District. To build the Zhejiang Taoshi brand, enhance core competitiveness, and achieve the group's goal of becoming stronger, more specialized, and more refined, the group has focused on management innovation and standardization application, as well as product quality, adhering to the principle of "customer-centric, quality through integrity." You only need to provide us with a concept or model of a new product, and we can deliver a perfect product, while ensuring the competitiveness of your product quality, cost, efficiency, and time, developing together with you to achieve a win-win situation.

Welcome your message

If you are interested in our products, please leave your needs, and we will contact you as soon as possible, thank you!